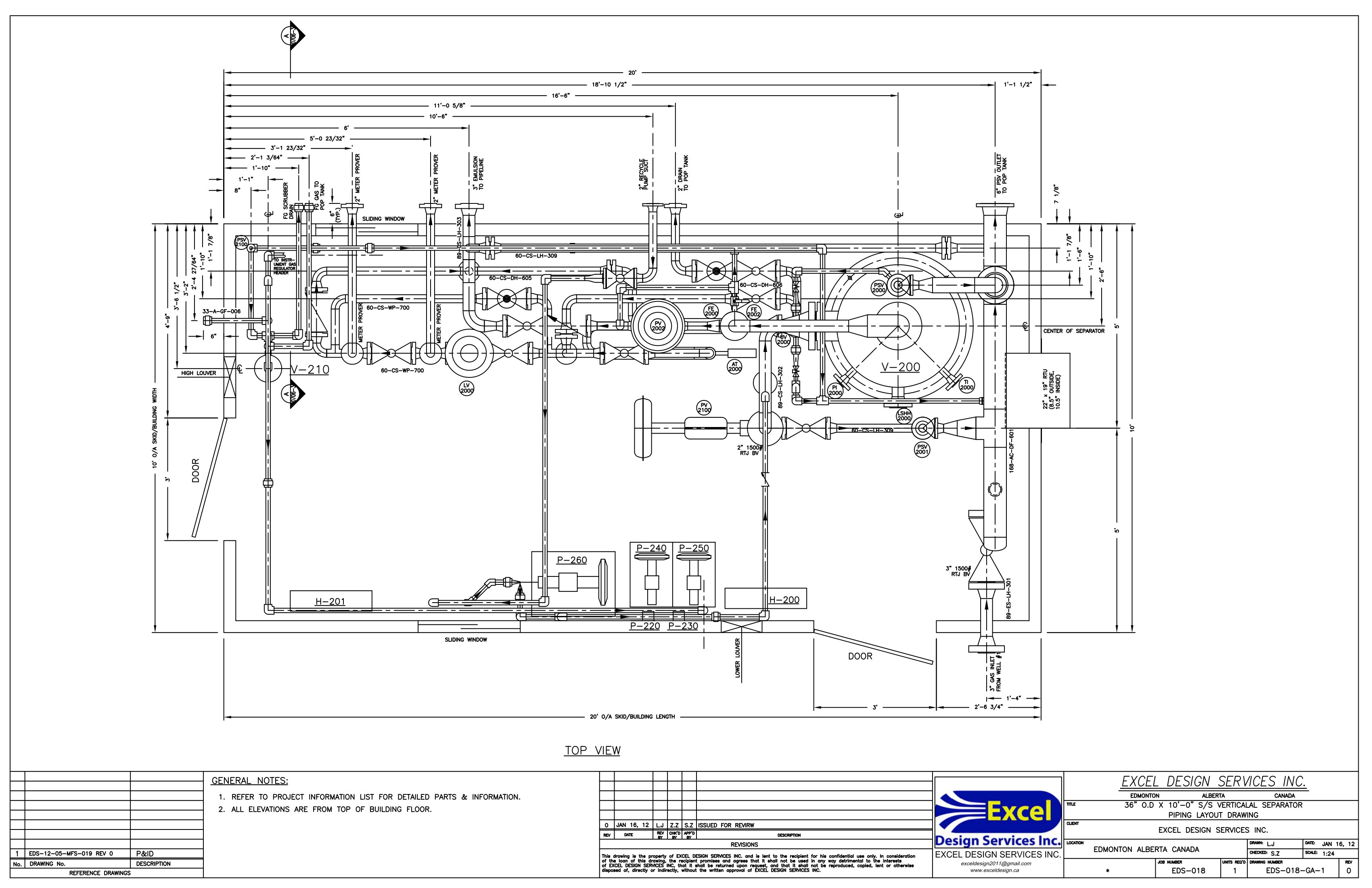

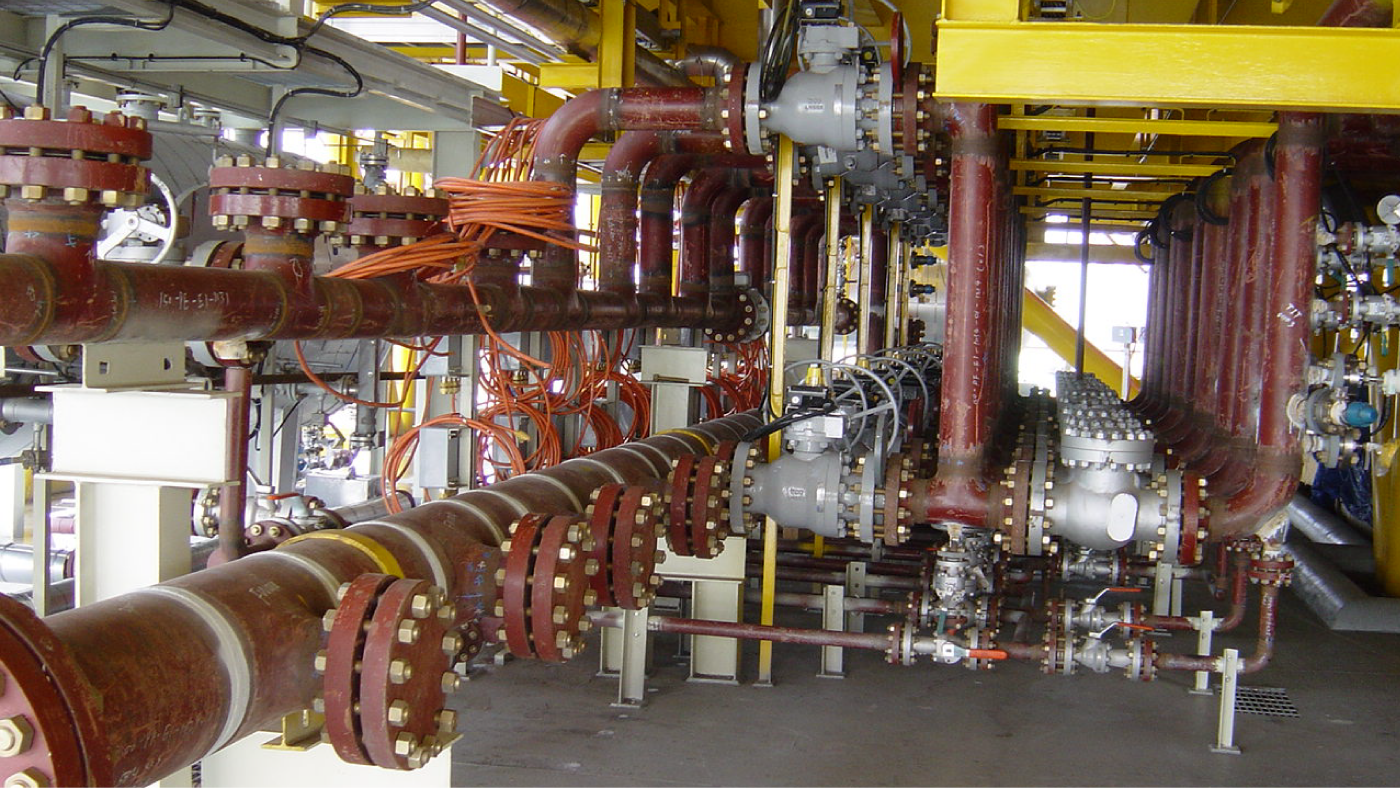

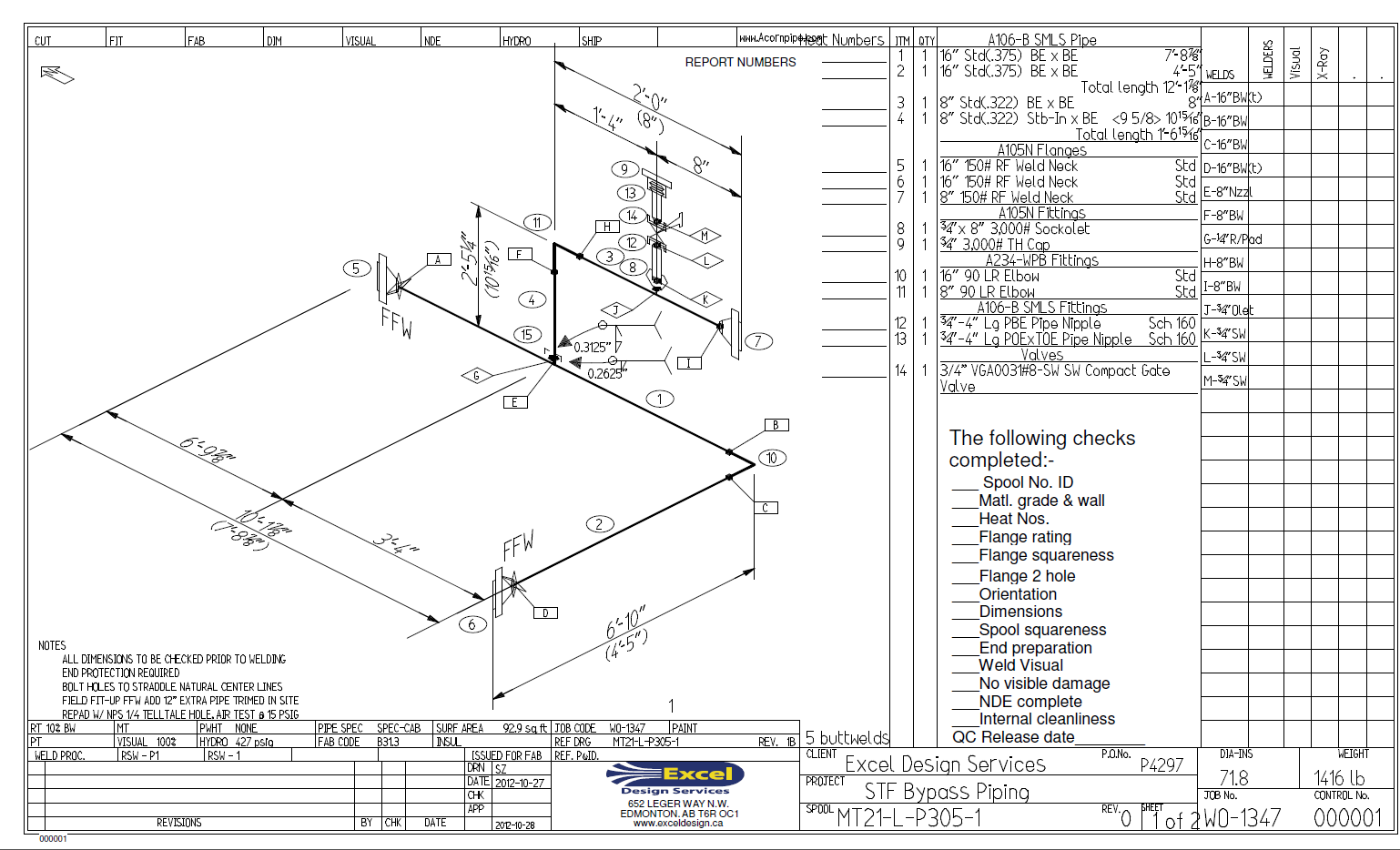

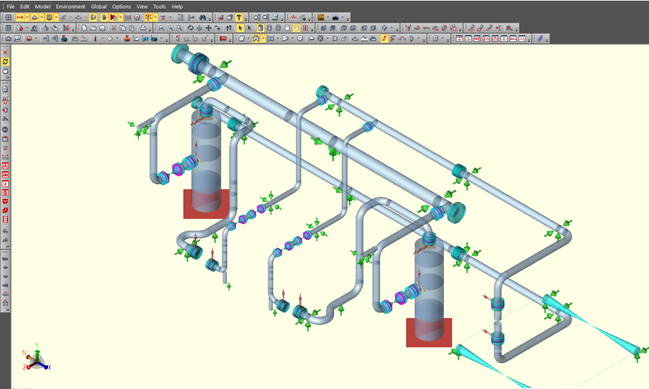

Engineering & DesignOur professional engineers and designers utilize their sufficient engineering design experiences, expertise, accuracy and excellent industry practices to provide pressure vessel, heat exchanger and tank engineering design and drafting, skid package design and drafting, fitting design and drafting, pressure piping engineering design and drafting, piping stress analysis, FEA and nozzle & clip local stress analysis, ASME certificate application or renewal design to our clients worldwide. |

||

|---|---|---|

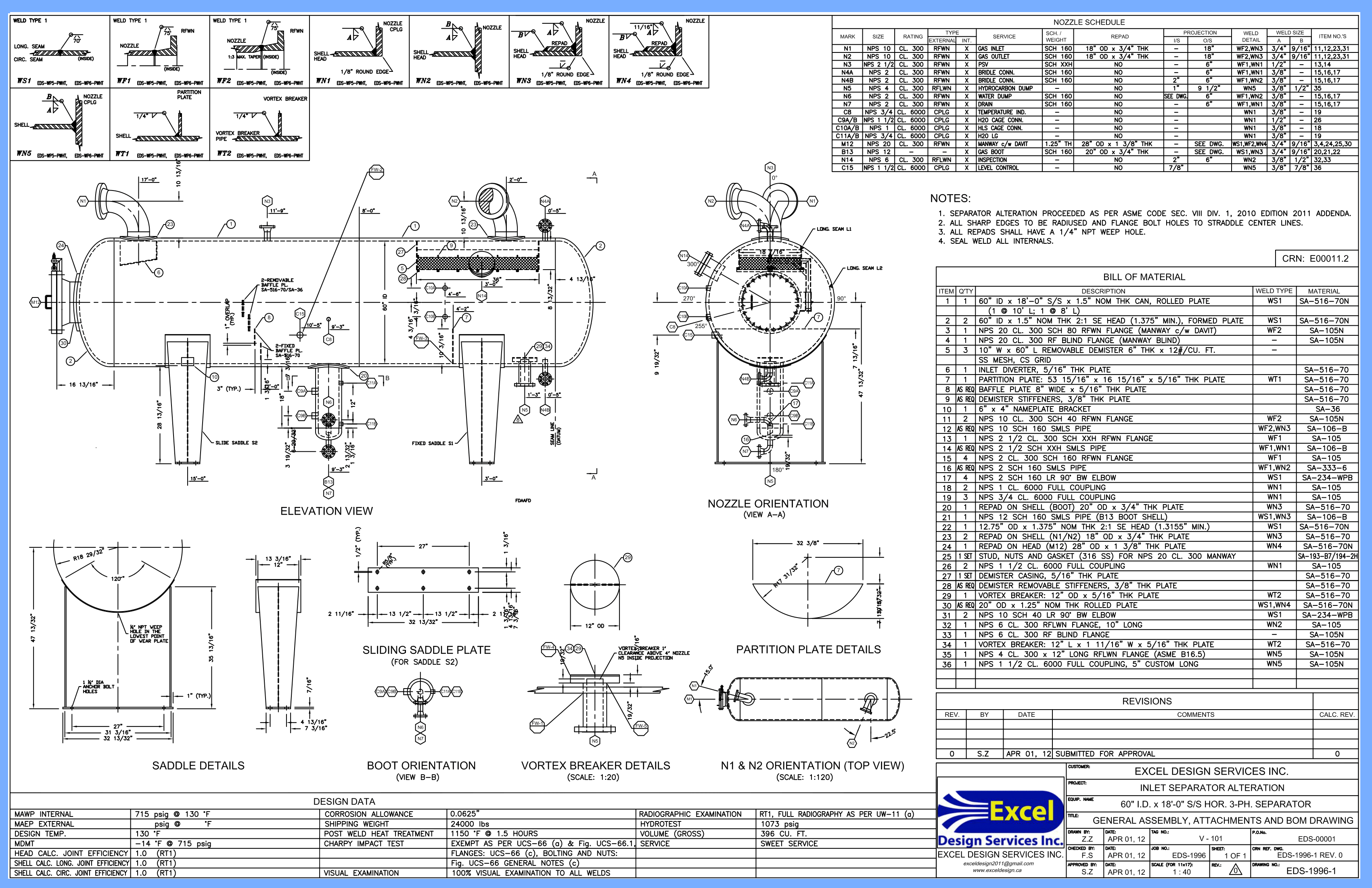

Pressure Vessel, Heat Exchanger and Tank Engineering Design and Drafting

Pressure Vessel, Heat Exchanger and Tank Engineering Design and Drafting

|

||

|

.png) |

|

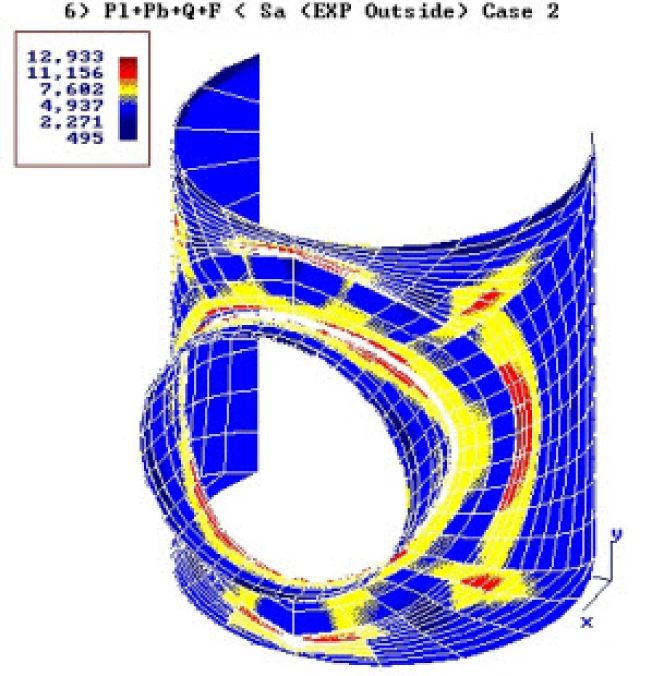

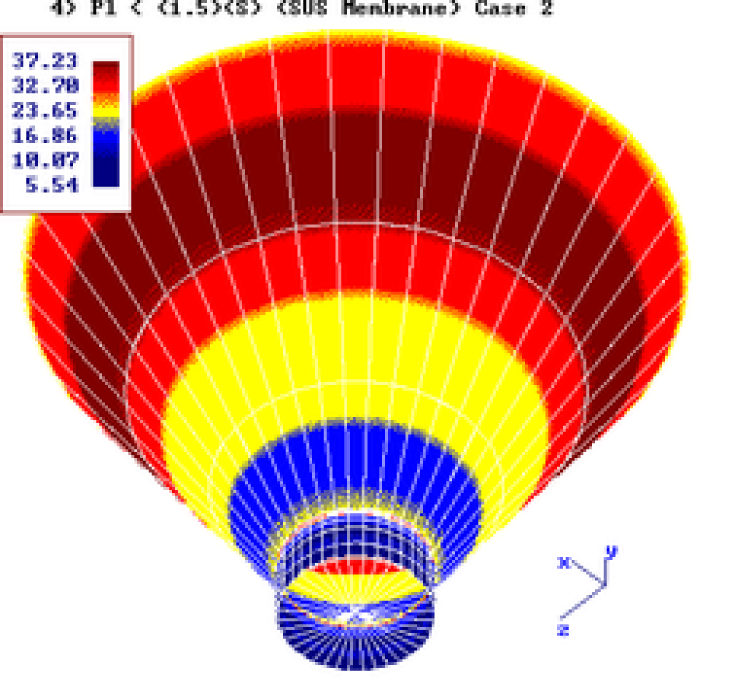

| Excel Design Services Inc. utilizes Codeware Compress software or our own flexible Excel calculation spreadsheet to design pressure vessel and heat exchanger as per ASME Sec. VIII Div. 1 & Div. 2, CSA B51, TEMA and client’s design specifications. We use AutoCAD to draft the scaled construction drawings. The regular engineering design process is we submit the engineering design package including design calculations and construction drawings to client for approval after finishing them, and then we submit the design package to Alberta Boilers Safety Association (ABSA) or the safety authorities of other provinces for Canadian Registration Number (CRN) registration after receiving the approval from client. Also, we offer the pressure vessel and heat exchanger re-rate, repair and alteration design calculation and drafting. | ||

|

|

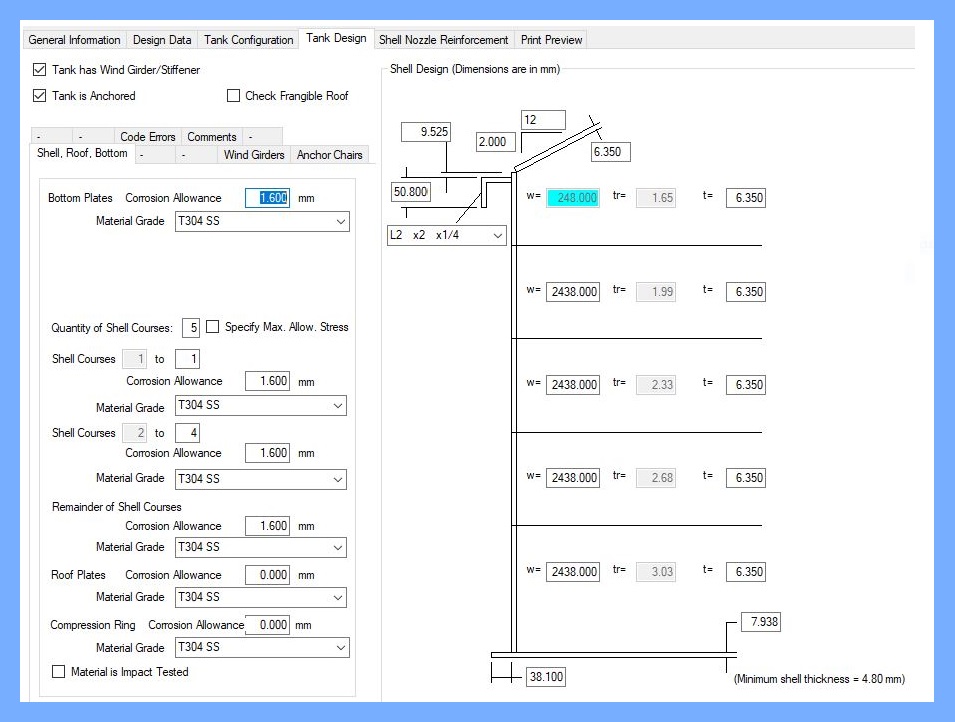

|

| We design the above-ground welded storage tank as per API 650, API 620, API 12F and client’s design specifications. In addition, we offer design for shop fabricated steel aboveground tanks as per ULC S601/S602 and steel underground tanks as per ULC S603. Excel Design Services Inc. also provides engineering design services to support tank site repair/alteration including tank bottom, shell, roof and nozzles as per API 653. | ||

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

Professional Member and Affiliations

Professional Member and Affiliations

-

The Association of Professional Engineers and Geoscientists of Alberta (APEGA)

The Association of Professional Engineers and Geoscientists of Alberta (APEGA)

-

Engineers and Geoscientists British Columbia (EGBC)

Engineers and Geoscientists British Columbia (EGBC) -

Association of Professional Engineers and Geoscientists of Saskatchewan (APEGS)

Association of Professional Engineers and Geoscientists of Saskatchewan (APEGS) -

Professional Engineers Ontario (PEO)

Professional Engineers Ontario (PEO) -

Canadian Welding Bureau (CWB)

Canadian Welding Bureau (CWB)